Waste & material traceability solution for sustainable facilities

The waste management landscape is experiencing unprecedented transformation as artificial intelligence evolves beyond basic sorting applications. While early AI implementations focused on replacing manual processes, 2025 brings sophisticated technologies that are redefining operational possibilities and delivering measurable financial returns across global facilities.

Recent industry analysis from European recycling facilities shows compelling ROI patterns emerging from AI implementations. German MRFs report average payback periods of 18-24 months, with operational cost reductions reaching 35% within the first year. These facilities process 40% more material volume while maintaining 97% sorting accuracy rates.

Nordic countries lead adoption with 78% of major facilities now incorporating AI-driven sorting systems. The financial impact extends beyond operational savings—premium pricing for cleaner material streams generates 15-20% higher revenue per ton compared to traditionally sorted materials.

Hyperspectral imaging combined with edge computing now enables real-time chemical composition analysis at conveyor speeds exceeding 3 meters per second. This advancement allows facilities to identify and separate materials previously considered non-recyclable, including complex multi-layer packaging and contaminated plastics.

Predictive analytics platforms analyze historical sorting data to anticipate equipment maintenance needs, reducing unplanned downtime by up to 60%. These systems correlate environmental factors, material composition changes, and equipment performance to optimize maintenance scheduling and prevent costly breakdowns.

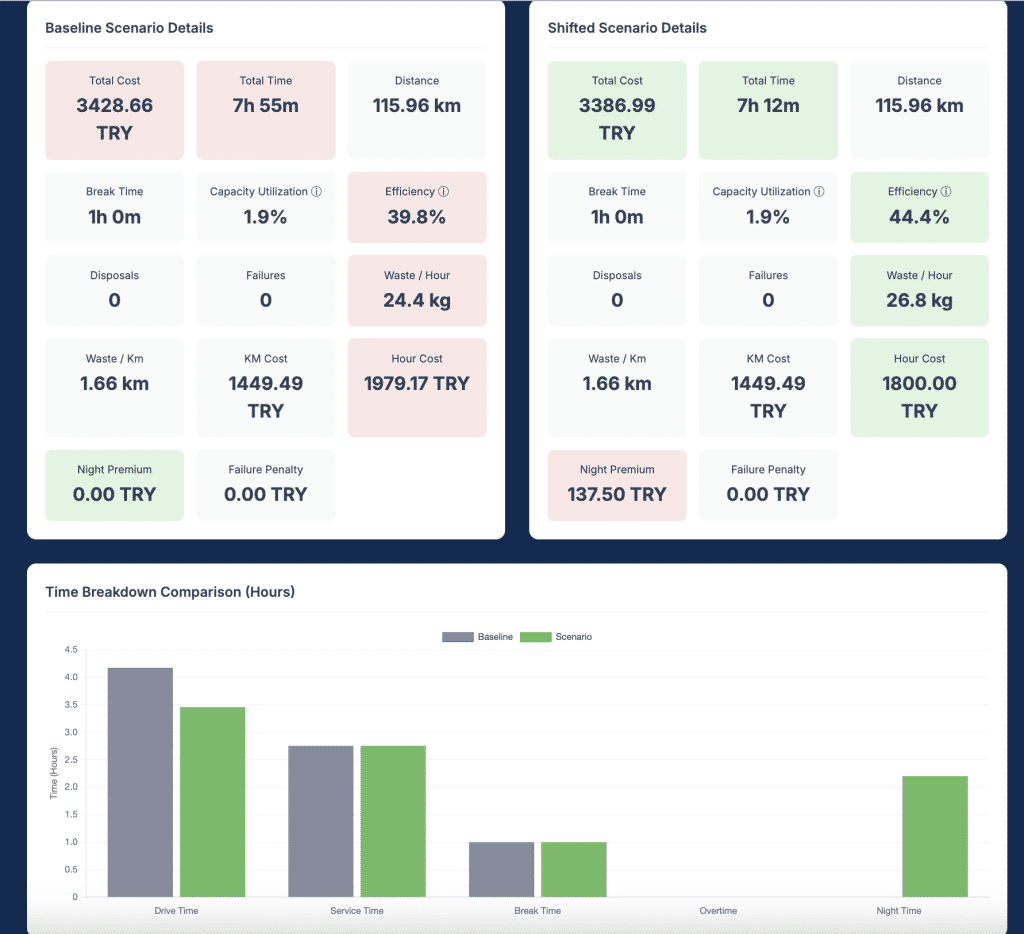

Digital twin technology creates virtual replicas of sorting facilities, enabling operators to test configuration changes and predict outcomes before implementation. This approach reduces trial-and-error periods and accelerates optimization processes.

Modern sorting systems generate detailed data about material flows, contamination rates, and

Japanese facilities demonstrate how AI sorting integrates with robotic systems to handle delicate materials like electronics and batteries. These installations achieve 99.2% accuracy in hazardous material identification while processing 25% faster than manual alternatives.

Australian MRFs showcase AI’s capability in handling seasonal variations, automatically adjusting sorting parameters during peak periods like post-holiday waste surges. This adaptability maintains consistent quality standards despite 40% volume fluctuations

Successful AI sorting implementation requires comprehensive data infrastructure connecting collection, processing, and reporting systems. Facilities achieving optimal results invest in integrated platforms that provide end-to-end visibility rather than standalone sorting solutions.

Workforce transition represents a critical success factor. Leading facilities report that retraining programs focusing on AI system monitoring and maintenance create higher-value roles while improving job satisfaction. This approach reduces resistance to technology adoption and accelerates implementation timelines.

Regulatory compliance becomes more complex with AI systems generating vast amounts of operational data. Facilities must ensure their technology choices support evolving reporting requirements and sustainability frameworks.

Emerging AI applications extend beyond sorting into predictive waste generation modeling and dynamic route optimization. These integrated approaches create circular economy ecosystems where sorting efficiency connects directly with collection optimization and customer engagement.

Quantum computing applications in waste management, while still experimental, promise to revolutionize complex optimization problems involving multiple variables and constraints. Early research suggests potential for solving facility-wide optimization challenges currently requiring significant computational resources.

The convergence of AI sorting with blockchain technology enables transparent material tracking from collection through final processing, supporting extended producer responsibility programs and circular economy initiatives.

Successful AI sorting adoption follows a structured approach beginning with comprehensive facility assessment and data infrastructure evaluation. Organizations must establish baseline performance metrics and identify specific improvement targets before technology selection.

Pilot implementations in controlled environments allow operators to understand system capabilities and limitations while developing operational procedures. This phase proves critical for workforce training and process optimization.

Scaled deployment requires integration with existing operational systems and comprehensive performance monitoring. Facilities achieving optimal results maintain continuous improvement programs that leverage AI system learning capabilities.

The future belongs to organizations viewing AI sorting as part of comprehensive digital transformation rather than isolated technology implementation. Success requires strategic vision, operational excellence, and commitment to continuous innovation in an rapidly evolving technological landscape.

Discover how Evreka can transform your facility’s efficiency and profitability. Request a demo today and see how smart technology can optimize your entire waste management ecosystem.