Waste & material traceability solution for sustainable facilities

The waste management industry is experiencing a technological revolution. While traditional waste segregation relies heavily on manual processes, smart waste sorting technology is transforming how facilities handle, process, and recover materials. This shift from manual to automated systems creates sustainable, profitable operations that meet the growing demands of modern waste management.

Smart waste sorting technology combines artificial intelligence, machine learning, and advanced sensor systems to identify, separate, and process different waste materials automatically. Unlike conventional methods, these systems operate 24/7, maintain consistent accuracy rates, and adapt to new waste streams without extensive retraining.

Modern waste sorting facilities adopt sophisticated technologies that integrate multiple solutions:

Advanced computer vision systems identify materials by shape, color, texture, and brand logos. These AI algorithms continuously learn and improve accuracy, effectively distinguishing between different plastics, metals, and recyclable materials.

Smart waste sorting technology creates unprecedented efficiency gains in Materials Recovery Facilities through automation and digital management.

Automated sorting systems process materials at speeds far exceeding human capabilities. While human sorters handle 40-60 items per minute, robotic systems process 200+ items per minute with 95%+ accuracy rates. This dramatic throughput increase allows facilities to handle larger volumes while maintaining quality standards.

Smart sorting technology significantly improves material recovery rates by reducing contamination and increasing sorted material purity. Higher purity levels translate directly into better market prices for recovered materials, improving overall profitability.

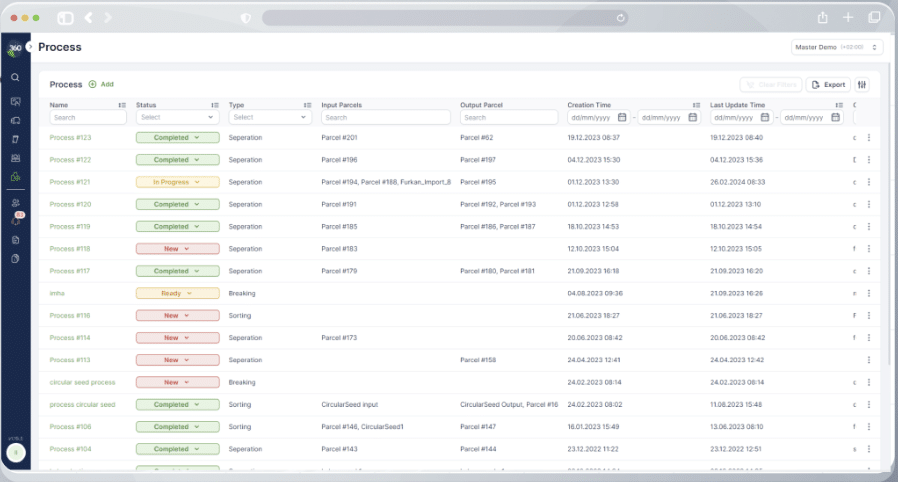

Evreka’s Materials Recovery Facility Management solution integrates seamlessly with these advanced sorting technologies, providing comprehensive oversight and optimization.

The waste management industry faces ongoing labor shortages and safety concerns. Manual sorting exposes workers to hazardous materials and repetitive strain injuries. Smart sorting technology reduces manual labor needs while removing workers from dangerous environments.

Contamination occurs when non-recyclable materials mix with recyclables, reducing batch value. AI-powered sorting systems excel at identifying and removing contaminants, maintaining quality and market value of recovered materials.

Modern sorting systems generate detailed data about material flows, contamination rates, and processing efficiency. This data supports regulatory compliance and integrates with operations management systems for real-time insights and automated reporting.

While initial investment in smart sorting technology can be substantial, long-term operational savings are significant. Reduced labor costs, lower error rates, and decreased downtime improve profitability. Many facilities see ROI within 2-3 years.

Higher purity levels achieved through automated sorting command premium prices in commodity markets. Clean, well-sorted materials sell for 20-30% more than contaminated materials, directly impacting the bottom line.

Smart sorting systems easily scale up or reconfigure to handle different waste streams, allowing facilities to adapt to changing market conditions and regulatory requirements without major infrastructure overhauls.

Smart waste sorting technology’s true power emerges when integrated with comprehensive digital platforms managing the entire waste management ecosystem. Modern facilities need integrated solutions connecting sorting operations with fleet management, route optimization, and customer engagement systems.

Advanced sorting systems generate vast data about material flows and processing efficiency. When integrated with platforms like Evreka360, this data becomes actionable intelligence driving operational improvements and strategic decision-making.

As AI systems process more data, their accuracy and efficiency continue improving. Future sorting systems will identify broader material ranges and adapt to new waste streams automatically.

Smart sorting technology plays a crucial role in circular economy initiatives by ensuring maximum material recovery and minimal landfill waste. As regulations become more stringent, these technologies become essential for compliance, including EPR compliance and sustainability reporting.

Smart waste sorting technology represents more than operational upgrade—it’s a strategic investment in waste management’s future. Facilities embracing these technologies today position themselves for long-term success in an increasingly competitive and regulated industry.

The combination of improved efficiency, reduced costs, enhanced safety, and better environmental outcomes makes smart sorting technology essential for modern waste management operations. When integrated with comprehensive digital platforms, these technologies create synergies driving unprecedented operational excellence.

Ready to revolutionize your waste sorting operations? Discover how Evreka’s integrated solutions can transform your facility’s efficiency and profitability. Request a demo today and see how smart technology can optimize your entire waste management ecosystem.

Transform your waste operations with cutting-edge sorting technology and comprehensive digital solutions. Contact Evreka to learn how our integrated platform can maximize your facility’s efficiency and profitability.